There are a number of problems that can cause the burner to fail to light. Following is a list of things to check:

1. Make sure the switches are turned ON, the doors are closed, and all the valves for the gas supply are turned ON.

2. When the thermostat knob is set to a temperature that is high enough to call for heat, is the red indicator light near the thermostat knob ON? If this light is not ON, turn the thermostat knob back and forth several times and watch to see if the light comes ON. Sometimes this will help clean the contacts inside the thermostat and help it to start working again. (There is a chance that the bulb in the red light may be burned out. If this is the case contact the service department to get a replacement bulb). The thermostat has two wire connections (one for incoming power and the other for outgoing power). There should be 120 VAC to a ground on each of these two wires if the thermostat is working correctly. If there is 120 VAC on only one, the thermostat may be bad.

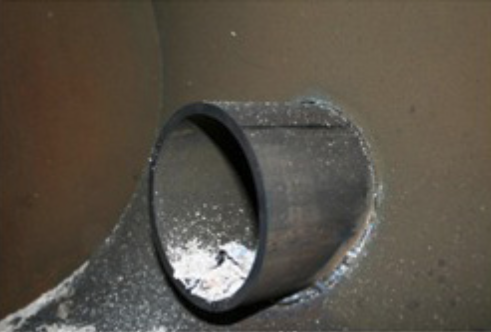

3. Ashes can accumulate in the burner tube where the flame normally comes into the fire box. In the bottom of this tube is the pilot burner-igniter assembly. If ashes build up to the point that the gas isn’t ignited by the spark, the burner won’t ignite. This can be cleaned by blowing compressed air into the burner tube, mainly in the bottom of this tube. Canned air can also be used (Make sure there is no fire burning in the fire box or any hot coals are removed as the propellant in these canned air products is propane). A shop vac can also be used.

4. The Hi Limit thermostat that may be tripped. This Hi Limit must be manually reset by pushing the red button. If there is click when this red button is pressed, the Hi Limit was tripped and should now be reset. The Hi Limit is designed to turn off the burner if the temperature inside the cooking chamber gets above 325 degrees. Cooking at very high temperatures can cause the Hi Limit to trip. The Hi Limit can be found inside the side compartment next to the drive chain on the EL series models. On the side loader models, it is in the end compartment where the drive motor and the fan motor is located. It should be on the side wall.

5. Before the burner will ignite, the combustion air blower motor on the top of the assembly must be running at full speed. If this is not running, the burner will not ignite.

6. The spark to ignite the burner is created by the ignition module, attached to the lower right side of the burner assembly. When this is working correctly, a clicking noise can be heard inside the fire box. This should continue for about 90 seconds after the thermostat is activated. If the combustion air blower motor is running and there is no clicking sound from the spark, the ignition module may be burned out. To test this, the orange spark cable can be unplugged from the ignition module and the end of the wire can be held close to the terminal where it was plugged in. If it is working correctly, a snapping spark should be visible. WRAP A DRY RAG AROUND THE WIRE OR WEAR A RUBBER GLOVE TO AVOID GETTING SHOCKED. If no spark is seen, the ignition module may have failed.

7. The combustion air blower motor has a centrifugal switch which is designed to prevent the burner from trying to ignite if the combustion air blower motor isn’t running at full speed. When the blower motor reaches full speed, a micro switch button completes the circuit to the ignition module. Occasionally, this micro switch can get dirty and not operate correctly. This micro switch can be cleaned and lubricated by spraying WD40 or a similar product on the motor shaft and the micro switch button. When working correctly, this button will move in and out freely.

If there is still no spark between the orange spark wire and the spark terminal on the ignition module, unplug the two wires attached to the 24v and 24V ground terminals on the ignition module. Check for voltage (24VAC) across these two wires with a volt meter.

If there is 24VAC across the two wires and there is no spark, the ignition module is not working and should be replaced.

8. If there is a spark but the burner is not lighting, the problem may be caused by the pilot burner not getting gas from the gas control valve. The gas control valve has two parts; the pilot flame side and the main flame side.

The pilot flame must light before the main flame with ignite. The gas to the pilot burner comes from a small tube that connects the gas control valve to the burner. The small pilot tube can be unscrewed from the burner end and pulled out of the hole. When the burner is sparking and trying to ignite, there should be a flow of gas from the end of this tube. If there is not gas coming from the tube, either a regulator may be stopping the gas flow or the gas control valve may not be working.

The blue wire connected to the gas control valve should have 24VAC when the burner is trying to ignite. If there is 24VAC at the blue wire and no gas is flowing out of the pilot tube, the gas control valve should be replaced.

If the pilot flame lights but the main flame does not, the pilot assembly located in the bottom of the burner tube may be dirty or ashes may have accumulated in the tube. The heat from the pilot flame must be sensed by the spark ignitor before the main flame will ignite. Blowing the spark ignitor and pilot burner with compressed air will clean these parts and may allow the main flame to light.

If cleaning the pilot assembly does not help, the main flame side of the gas control valve may be sticking and not opening to allow the gas to flow to the burner. With the pilot flame burning, the red wire can be unplugged from the gas control valve and tested with a volt meter. There should be 24VAC between the red wire and a ground. If there is 24VAC present and the main flame is not igniting, the gas control valve should be replaced.